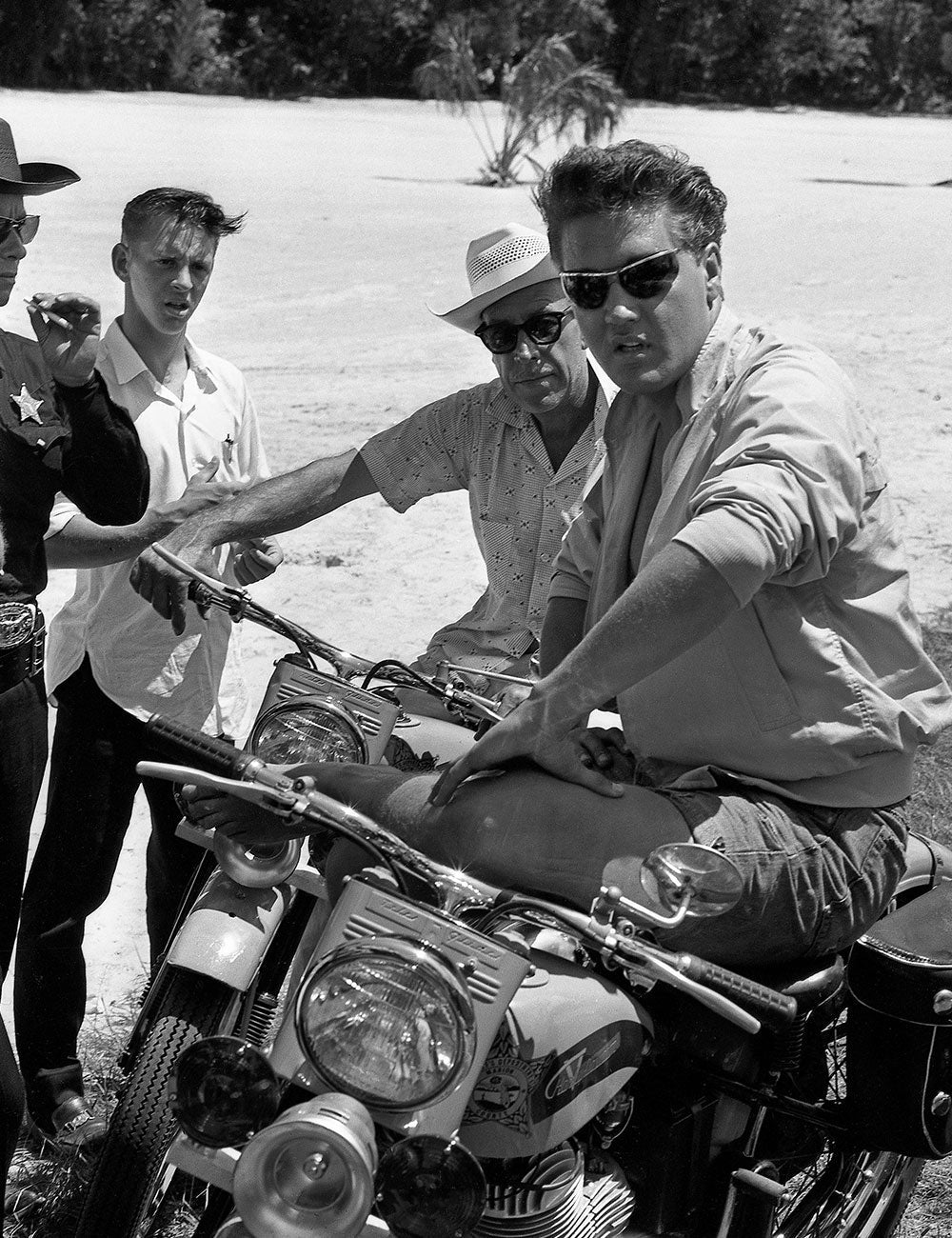

A PIONEERING VISION

Each pair of limited edition Renauld sunglasses has a narrative told through its connection to high profile figures in history and the design and craft techniques used in its creation. We combine our craft legacy with cutting-edge technology and it is this unusual and pioneering combination that sets us apart from others.

We take the utmost care in creating an aesthetic which remains distinct yet timeless using only the finest materials in each frame and lens which are designed and made to exceptional optical performance and durability standards.

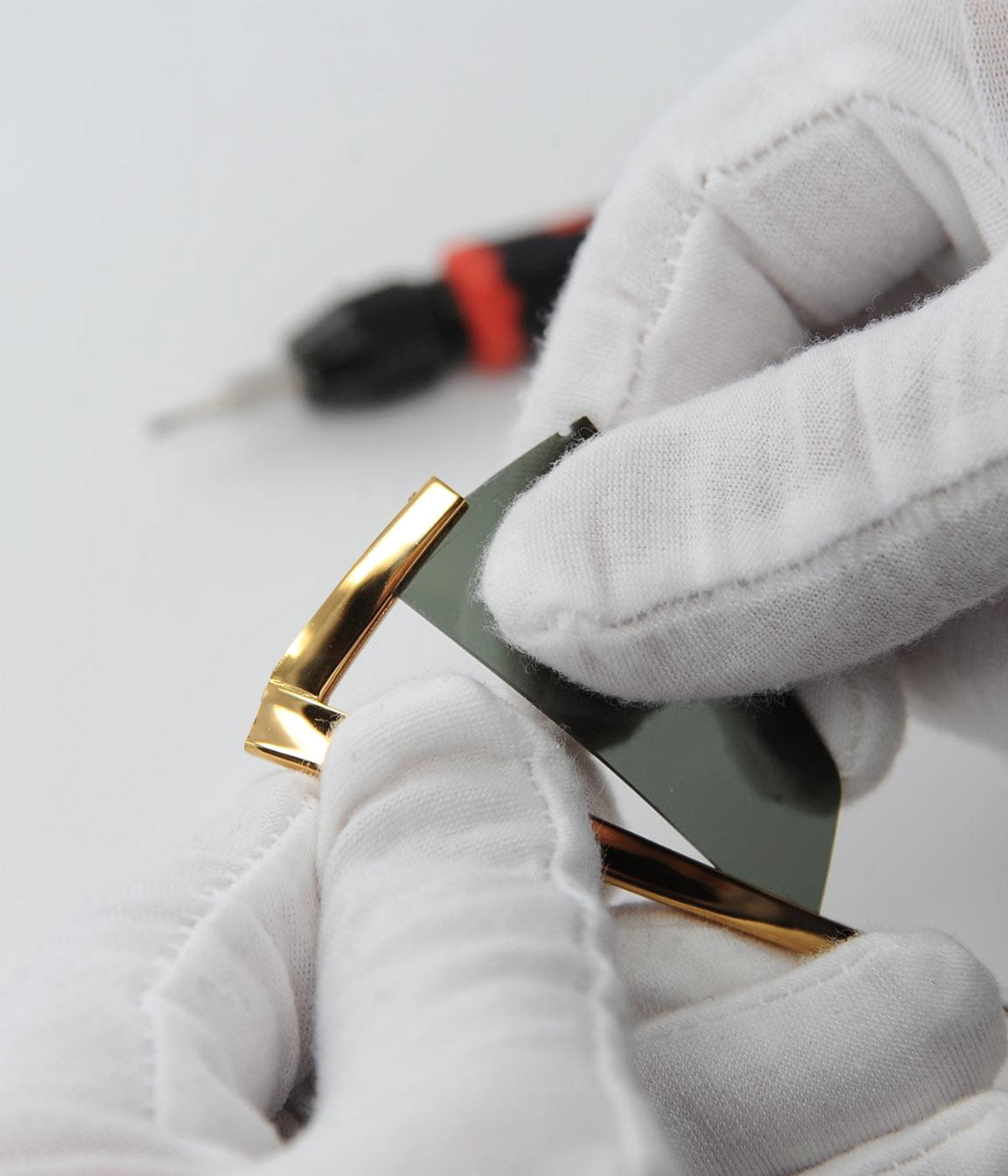

Handcrafted in the Renauld Studios near Venice, Italy, each design can take up to 18 months from initial concept to retail. Three to nine months of which is spent creating the sunglasses across nine studios, each specialising in a particular area of artisanal and production expertise.

We use only the finest raw materials including the alloy known as alpaca metal, chosen because it is highly durable, and plated in 24ct yellow gold, 24ct rose gold, and palladium precious metals. We also use cellulose acetate, a respected and renewable plant-based and non-petroleum material with hypoallergenic properties.

Our Renauld narrative starts with us exploring our archives, looking to re-interpret designs from our past, or choosing a moment-in-time or an individual that we think captures the essence of Renauld. After the design is signed off, a mould is made that is worked and re-worked until it is the absolute epitome of perfection. It is then put into production. From here, each component is individually stamped before it is assembled by hand and put through a rigorous quality assessment before being made available to our customers.

Renauld prides itself on creating designs that are extremely technically challenging. The distinct shape of our iconic wrap sunglasses flows from the simultaneous confluence of three curves in three dimensions. Our signature polymer lenses are known to be some of the most curved in the world, with Base 11-14 moulded into the correct specification using the highest quality anti-glare UV400 lenses, made by DIVEL, that are optically accurate and do not distort shapes and lines. This exacting specification requires synchronised five-axis milling across three perpendicular planes; a proprietary technique without equal in sunglasses manufacture. This extreme wraparound base level curvature means that Renauld lenses offer 180-degree, uninterrupted protection.

Lenses come in a variety of colours guaranteeing 100% UVA and UVB protection up to 400 nanometres.

Each pair of Renauld sunglasses have their own serial number etched into the temple and are accompanied by a signed certificate of authentication.